High-tech materials have moved beyond the preserve of elite ski athletes. These days, skiers across all levels exploit ground-breaking materials technology

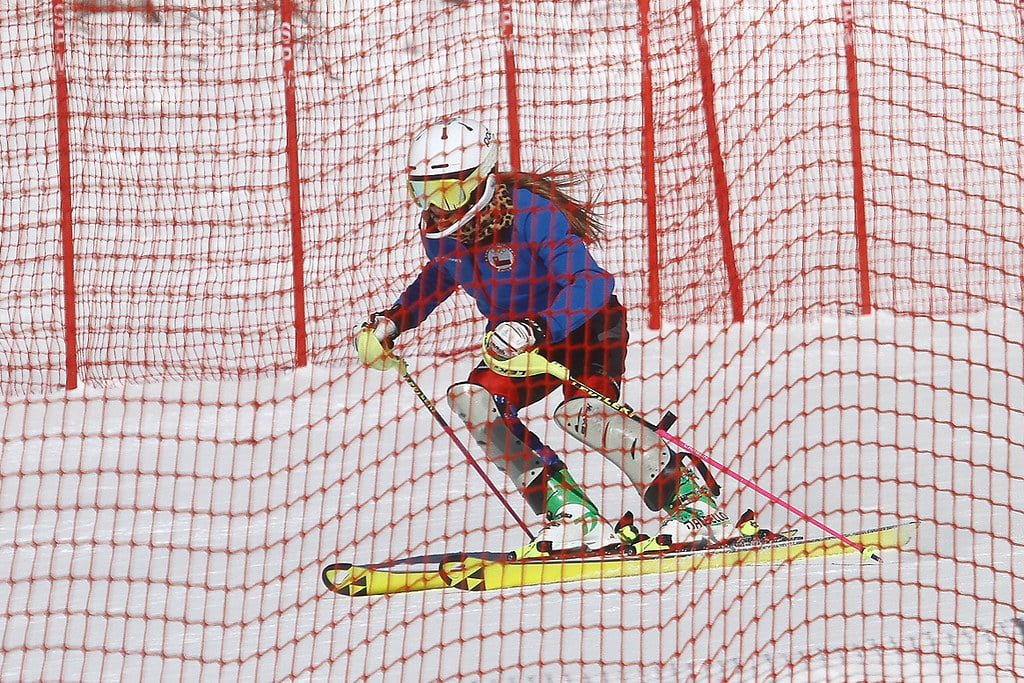

Emerging materials and novel hybrid ski designs have changed Olympic skiing. (Mauricio Palma and Comunicaciones COCH, Flickr) : Mauricio Palma and Comunicaciones COCH, Flickr

Emerging materials and novel hybrid ski designs have changed Olympic skiing. (Mauricio Palma and Comunicaciones COCH, Flickr) : Mauricio Palma and Comunicaciones COCH, Flickr

High-tech materials have moved beyond the preserve of elite ski athletes. These days, skiers across all levels exploit ground-breaking materials technology

By Marc Zupan, UMBC – University of Maryland, Baltimore County

While the pandemic may have interrupted skiing holidays, the development and implementation of new materials into skis progressed with pace.

The speed of progress becomes clear when looking at a standard set of rental skis with the words ‘LYT DONE RIGHT: MULTILAYER CARBON. KARUBA. GRAPHENE’. Some of the most advanced individual materials are brought together in the ski. Carbon fibre akin to those used in advanced air and spacecraft, specifically chosen low-density stiff wood called Karuba (Paulownia spp.) for weight, and graphene for strength.

Graphene is an emerging material discovered in the early 2000s. Only one atomic layer thick, it is used in a variety of applications ranging from targeted drug delivery, electronics and semiconductors, energy, membranes, to creating drinking water and ultralight sensors. These have been hybridised into a ski that an amateur can purchase and even routinely rent.

Alpine skiing is one of the most popular winter activities, with millions of people participating annually worldwide. New skiing equipment develops quickly, and the competition between ski manufacturers is acute.

The effects of modern equipment are apparent at the professional and Olympic levels, and all the way down to the recreational level. The modern ski is shorter, lightweight, durable, and easier to use.

Advances in equipment have contributed to Olympic records tumbling, and also the popularity of skiing as a broad recreational pursuit, where the progress is manifested in shorter learning periods, increased comfort and safety, and a more rewarding experience. The drive for new technologies and new material selection in designs is further accelerated in response to the growing demand for equipment.

The alpine ski has evolved through the years in a fairly predictable manner but has undergone more radical changes in recent years due to improved design and manufacturing technology. The advanced materials selected reflect the need to balance performance with protection against injury.

Skis are selected according to a skier’s weight, height and ability to handle the slopes. That’s why when buying or renting skis vendors ask those questions. Overall skiing performance is a result of both the user and the equipment. Bad equipment hinders a great skier; good equipment lifts the amateur person up. Many factors determine performance and they interact in complex ways with each other.

Skiing is a highly dynamic sport with several forces acting on the skis simultaneously. The pressure on the skis, resulting from the speed and body weight, is constantly shifted from one side of the ski to the other, exposing the skis to high forces at their edges. The pressure also varies as a function of the skier’s speed, radius of turn, and terrain conditions. If the skier is too heavy for the type of ski chosen, it will cause ‘chatter’ and poor edge control, especially under icy or hard snow conditions. Underloading, where the skier is too light for the ski, on the other hand, leads to difficulties in turn initiation, particularly in soft or deep snow.

In early ski design and construction, concepts were limited primarily by material availability. Wood was the obvious choice; it was readily available, its properties and characteristics were reasonably well understood, and woodworking was an established practice. Wood could be handcrafted or machined and formed to shape.

Despite its apparent advantages, wood has negative characteristics. Because of its fibrous structure, it is anisotropic – strong in some directions, but not others. Wood does not respond well to twisting forces and it can be sensitive to humidity and moisture, which can increase its weight and result in distortion and warping.

Ski designers and manufactures moved from traditional monolithic wood structures and incorporated plastic bases, steel edges, aluminum alloy structural members, and high strength engineered fibres, including but not limited to carbon, kevlar, glass, and graphene.

Performance improvements through new metal alloys and new polymer compositions are often incremental, time-consuming, uncertain, and expensive. To leapfrog the materials selection and design process, manufacturers not only implement the newest emerging materials but they leverage the opportunities that ‘hybrid materials’ provide, hence the tag ‘LYT DONE RIGHT: MULTILAYER CARBON. KARUBA. GRAPHENE’.

Combining two or more existing materials allows a superposition of their properties. Ski designers use hybrids to create ‘new’ material performance capabilities filling gaps in the desired material performance. Hybrid materials with specific design-led property performance metrics tailor flex and torsion according to performance requirements.

Structural members of stiff, strong skins separated by a lightweight core, known as sandwich panels, now embody the modern ski. This construction allows the flex of the ski to be tailored while remaining light-weight. The stiffness of a ski is critical in giving the skier performance. A ski that is too soft will be challenging to control. Conversely, an overly stiff design will not allow the user to carve a turn or manoeuvre.

Reduced weight with tailored stiffness and strength enables an athlete to push the limits of their performance. With the unique alpine downhill course of the Beijing Olympics already causing trouble among athletes on early days of the competition, this will be more evident than ever.

Modern ski hybrid materials combinations may include more than 30 different sub-components created from various material types. They can give a progressive change in stiffness or other mechanical response along the length of the ski. The design provides the combination of properties that offer performance, safety, and response while keeping the weight low.

High technology is typically associated with Olympic and competitive skiing, implying a high degree of performance under extreme conditions, including high speeds and challenging terrain.

But even rental skis now exploit hybrid technologies and the most advanced materials. The modern hybrid ski’s performance metric is also based on the ease of operation at the beginner level and the contribution to the learning process for the developing skier. The beginner skier can rapidly advance to the intermediate level, and broadly skiers are much better equipped to attain expert status, a category of skills once reserved for only a small fraction of recreational skiers.

Emerging materials and novel hybrid ski designs have and will continue to transform Olympic and professional-level racing and have opened new avenues in the sport of skiing to less gifted athletes.

Marc Zupan is an Associate Professor of Solid Mechanics and Materials in the Department of Mechanical Engineering at UMBC – University of Maryland, Baltimore County. His research targets novel weight-efficient composite hybrid sandwich panels for vehicle systems enabling design lead optimisation of material selection in a multidisciplinary design space.

Originally published under Creative Commons by 360info™.

Editors Note: Marc Zupan in Baltimore County